1. Introduction to Soft Capsule Encapsulation Machines

In the pharmaceutical and nutraceutical industries, the demand for effective and versatile drug delivery systems has increased significantly. Among the array of available technologies, soft capsule encapsulation stands out due to its ability to enhance bioavailability and improve patient compliance. Soft Capsule Encapsulation Machines play a pivotal role in producing these advanced dosage forms, enabling manufacturers to meet the increasing consumer demands while adhering to stringent regulatory standards.

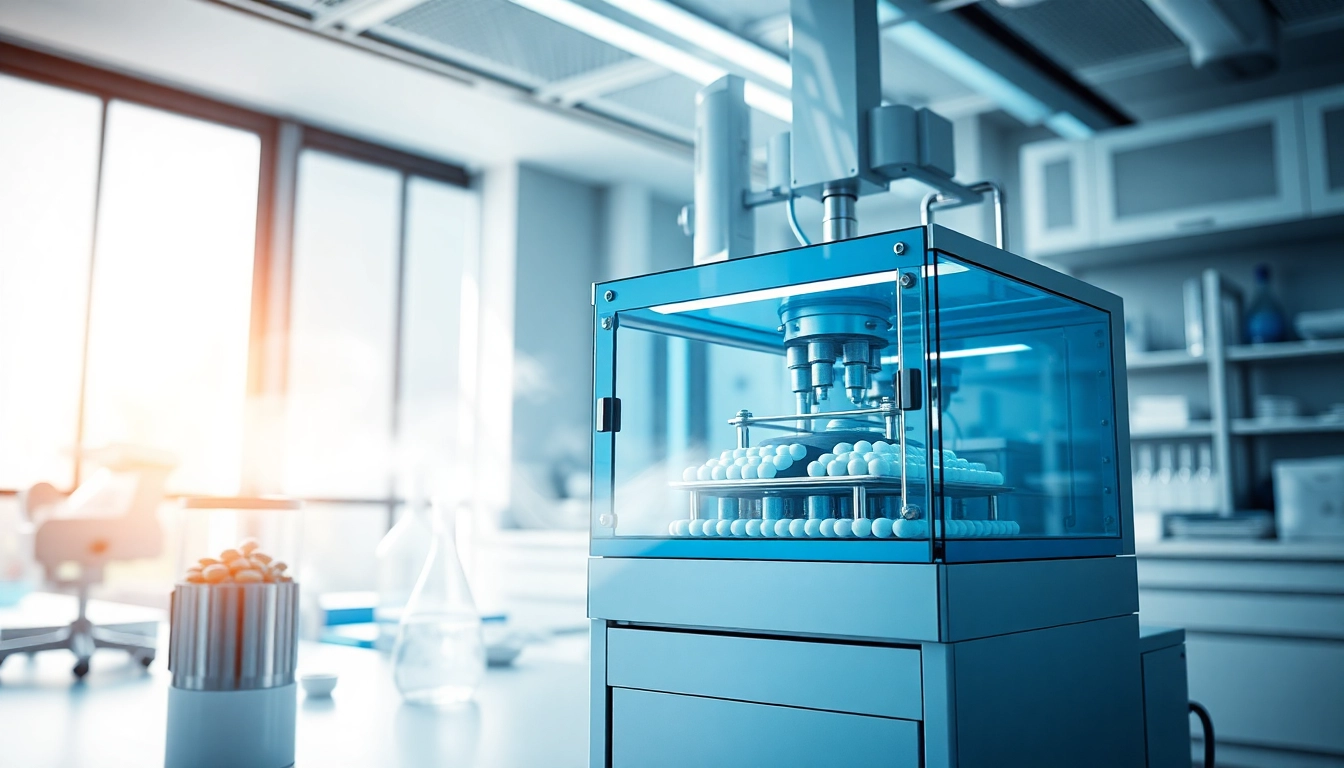

1.1 What are Soft Capsule Encapsulation Machines?

Soft capsule encapsulation machines are specialized equipment designed to produce soft gelatin capsules, which are typically composed of gelatin, water, and plasticizers. These machines utilize various technologies to create the capsule shell and fill it with liquid or semi-solid formulations containing active pharmaceutical ingredients (APIs), as well as excipients. The capsules’ soft gel coating enhances absorption in the body, making them a popular choice for delivering oil-soluble vitamins and other nutrients.

1.2 Importance in Pharmaceutical Manufacturing

The significance of soft capsule encapsulation machines in pharmaceutical manufacturing cannot be overstated. Unlike traditional tablet forms, soft capsules offer several advantages, such as:

- Higher absorption rates: The soft gel formulation allows for better solubility and faster absorption of ingredients.

- Masking of taste and odor: Soft capsules can effectively cover the flavor of unpleasant-active ingredients, improving user experience.

- Dose flexibility: These machines can handle a wide range of dosages, catering to various patient needs without compromising the formulation integrity.

- Enhanced stability: Soft capsules often have fewer degradation issues compared to other dosage forms, particularly for sensitive ingredients.

1.3 Overview of Encapsulation Processes

The encapsulation process in soft capsule production occurs in a series of steps involving accurate measurement, mixing, and filling. Initially, the capsule shell components are blended and heated to achieve a specific viscosity. Once the shell is prepared, the desired formulation is injected into each gelatin form before sealing the capsules. This process not only protects the active ingredients from environmental factors but also ensures a consistent release profile, contributing to the overall effectiveness of the drug.

2. Types of Soft Capsule Encapsulation Machines

Soft capsule encapsulation machines come in various designs and functionalities, catering to a wide array of manufacturing needs. Understanding these variations is vital for businesses looking to optimize their production processes.

2.1 Common Variations and Technologies

Soft capsule encapsulation machines can generally be categorized into several types based on their functionality and technology:

- Rotary machines: These machines feature a rotating drum that transfers the gelatin mass into the encapsulation molds, making them suitable for high-volume productions.

- Automatic and semi-automatic machines: While automatic machines perform the entire encapsulation process with minimal human intervention, semi-automatic systems require some manual input, often making them more cost-effective for smaller production runs.

- High-viscosity encapsulation machines: Designed for filling thick formulations that might be challenging for traditional machines, these systems provide additional mixing and pumping capabilities.

2.2 Comparing Manual vs. Automated Machines

When it comes to choosing between manual and automated soft capsule encapsulation machines, several factors must be considered:

- Production capacity: Automated machines typically yield higher output, which is essential for large-scale manufacturers, while manual options may suffice for smaller operations.

- Labor costs: Automated systems can reduce labor costs due to less human intervention needed, but the initial investment is higher compared to manual machines.

- Flexibility: Manual machines might offer more versatility for small batch productions or novel formulations due to their hands-on nature.

2.3 Specialized Machines for Different Applications

In addition to general types, there are specialized soft capsule encapsulation machines designed for specific applications, such as:

- Fish oil and omega-3 capsule machines: These machines are equipped to handle highly viscous and sensitive filling materials to preserve their integrity.

- Pharmaceutical-grade encapsulation systems: Often meeting strict regulatory standards, these machines ensure product quality and safety for medical applications.

- Nutrition and dietary supplement machines: Tailored for the nutraceutical market, these machines focus on a vast range of formulations, including herbal extracts and nutritional oils.

3. Benefits of Soft Capsule Encapsulation Machines

The adoption of soft capsule encapsulation machines brings numerous benefits to pharmaceutical manufacturers. Understanding these advantages can highlight the value of investing in the right technology.

3.1 Enhanced Product Stability and Efficacy

One of the primary benefits of soft capsules is their ability to maintain the stability of active ingredients by protecting them from light, air, and moisture. This encapsulation technique ensures that the efficacy of sensitive compounds is preserved throughout their shelf life.

3.2 Improved Bioavailability of Active Ingredients

Bioavailability refers to the degree and rate at which the active ingredient or active moiety is absorbed and becomes available at the site of action. Soft capsules enhance bioavailability by dissolving quickly upon ingestion and enabling direct absorption in the gastrointestinal tract, thereby leading to faster onset of action and improved therapeutic responses.

3.3 Cost-Efficiency and Scalability in Production

Employing soft capsule encapsulation machines allows manufacturers to attain cost efficiencies through streamlined production processes and reduced raw material waste. Additionally, the ability to scale up production seamlessly caters to increasing demand without detriment to product quality or consistency.

4. Challenges in Using Soft Capsule Encapsulation Machines

While soft capsule encapsulation machines offer significant advantages, there are challenges manufacturers may face when integrating these systems into their production lines.

4.1 Common Manufacturing Issues

Some of the common challenges encountered include:

- Gelatin quality issues: Variability in gelatin quality can lead to inconsistencies in capsule formation and shell integrity.

- Filling inaccuracies: Fluctuations in filling weights can result in over or under-dosed capsules, which poses risks to product efficacy and regulatory compliance.

- Clogging and maintenance problems: The accumulation of residues in the dispensing nozzles can lead to production downtime and increased maintenance costs.

4.2 Maintenance and Operational Challenges

Regular maintenance is crucial for ensuring the longevity and optimal performance of soft capsule encapsulation machines. Operational challenges, such as machine calibration and troubleshooting, can significantly impact production timelines and costs if not addressed promptly.

4.3 Regulatory Compliance Considerations

As the pharmaceutical industry is highly regulated, manufacturers must ensure that their soft capsule encapsulation processes comply with local and international guidelines. These regulations cover aspects like quality control, safety standards, and Good Manufacturing Practices (GMP), which increases the complexity of production.

5. Future Trends in Soft Capsule Encapsulation Technologies

The landscape of soft capsule encapsulation machines is evolving continuously, influenced by technological advancements and market demands. Here are some of the future trends shaping the industry.

5.1 Innovations Shaping the Industry

Emerging technologies such as continuous manufacturing capabilities, 3D printing, and automated quality control systems are revolutionizing soft capsule production. These innovations aim to create more efficient, flexible, and precise production processes while minimizing human error.

5.2 Sustainability and Eco-Friendly Practices

As sustainability becomes increasingly paramount in manufacturing, companies are exploring biodegradable polymers and sustainable sourcing for gelatin alternatives. Investing in eco-friendly practices not only meets consumer expectations but also anticipates forthcoming regulatory requirements concerning environmental impact.

5.3 The Role of Technology in Advancements

Technology plays a vital role in enhancing the performance and efficiency of soft capsule encapsulation machines. Innovations such as Internet of Things (IoT) integration and predictive maintenance can help manufacturers optimize their operations, reduce downtime, and respond proactively to maintenance needs.